ABQ Button Tensile tester

The button Tensile tester can be equipped with NK, HF push-pull force gauges and special fixtures. Specially used to measure the clamping force of buttons or the collapse force when they are separated from clothing. Testing the fixation strength of the bu

ABQ Button Tensile tester

Manual Screw Button Pull Force Test Stand

Introduce:

The button Tensile tester can be equipped with NK, HF push-pull force gauges and special fixtures. Specially used to measure the clamping force of buttons or the collapse force when they are separated from clothing. Testing the fixation strength of the button is a very important criterion. In particular, the design and manufacturing of infant and child clothing is most important. A force meter is required to record the measurement of force on the fixed decorative buckle.

Function:

1. The test method of this instrument is used to measure buttons and clothing for vertical pull testing. The buttons and buttons do not need to be pulled from the clothing.

2. This method requires that the button sewing specifications should comply with the button manufacturer's standards.

3. This testing method is used to establish correlation in different environments and compare various buttons and brands.

4. This standard may contain hazardous materials and equipment. However, we do not list all safety issues that may arise during use within the standard. It is therefore the responsibility of users of standards to establish rules regarding safety and health and to determine appropriate rules before use.

5. All buttons need to be sewn tightly on the fabric using chain sewing.

6. According to the test requirements, when the maximum size of the button is greater than or less than/equal to 6mm, the button should withstand a pulling force of 90N or 50N respectively.

Features:

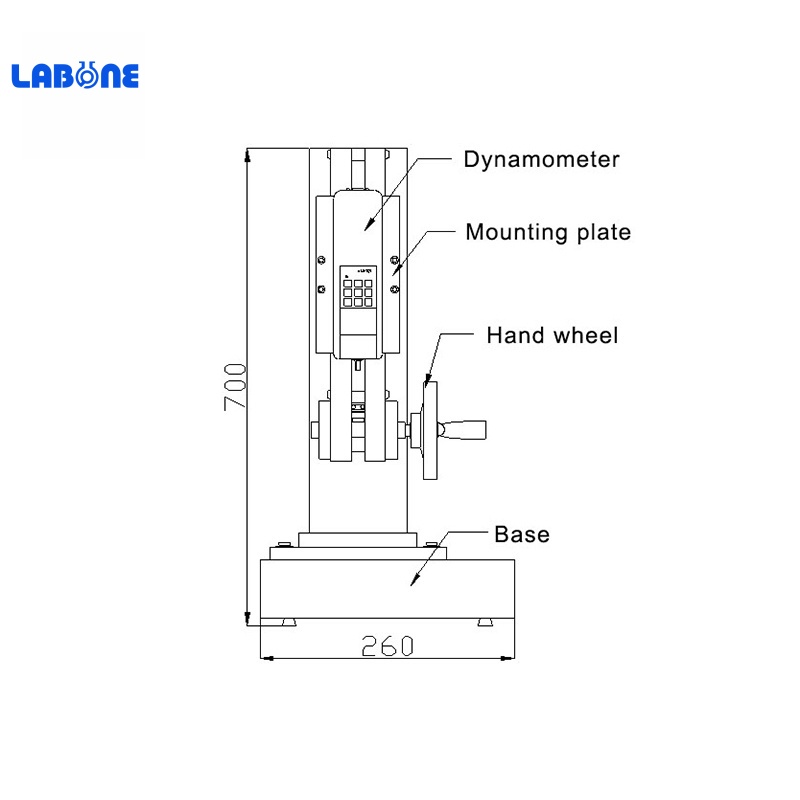

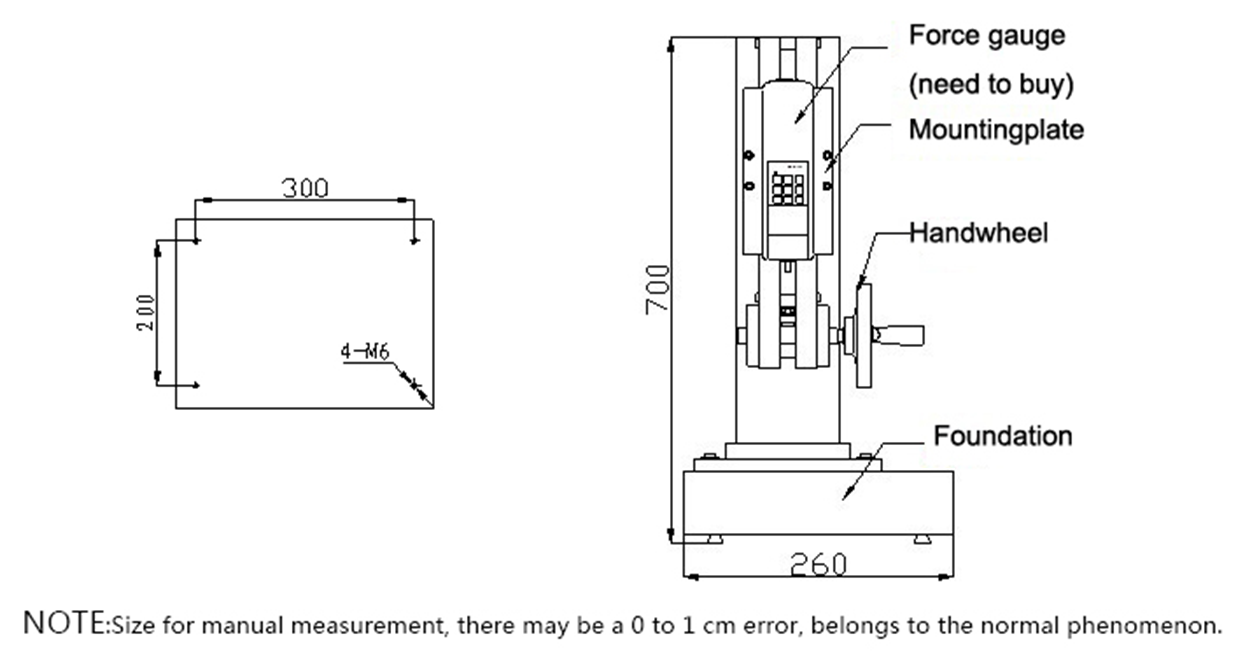

Large base platform, good stability, suitable for indoor desktop testing.

Screw drive, precision displacement measuring head, transverse handwheel loading, simple and stable operation.

The standard configuration base platform can be moved left and right to facilitate precise clamping.

This machine can be installed on a workbench (platform) to make the rack more stable.

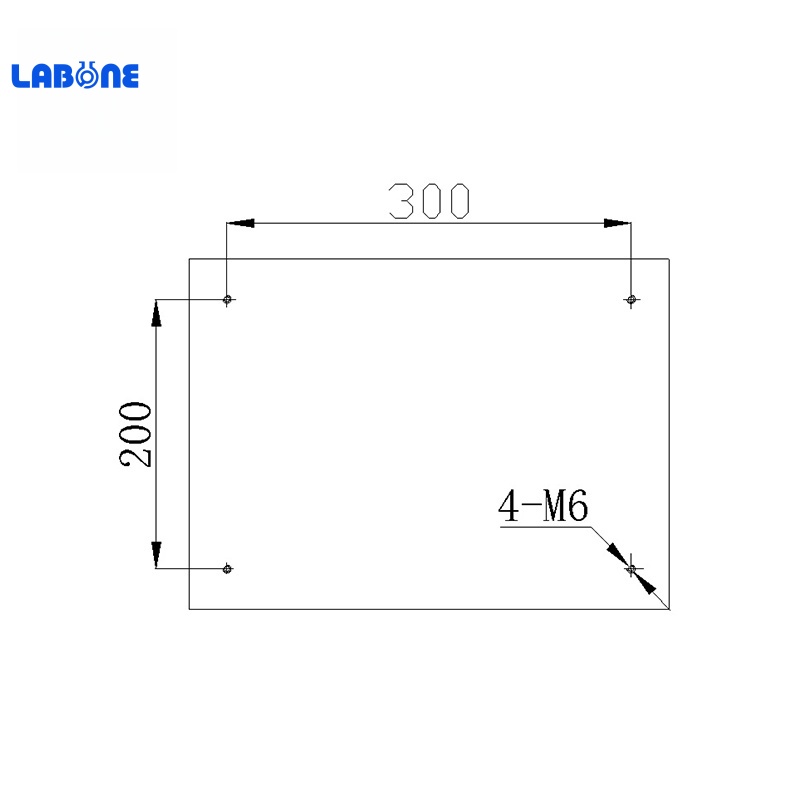

Size | 260mm*360mm*700mm |

Trip | 180mm |

Rated load | 500N |

1. The push-pull force gauge of the instrument: the standard configuration is the pointer push-pull force gauge NK-300

(It can also be equipped with digital display push-pull force meter HF-300, the price is different)

⑴ Pointer push-pull force gauge

Model | NK-300 |

Maximum load | 300N (30Kg) |

Stroke of push-pull rod | 10mm |

Working temperature | 20 ℃ ± 10 ℃ |

Transportation temperature | -27 ℃ ~ + 70 ℃ |

Relative humidity | 15% ~ 80% RH |

Working environment | there are no vibrating sources and corrosive media around |

⑵ Digital display push-pull force gauge

Model | HF-300 |

Maximum load | 300N (Kg, N and ib three units can be automatically converted) |

Resolution | 0.01N |

Accuracy | ± 0.5% |

Output interface | RS 232 nine-hole socket |

Charging power supply | 220V / AC |

continuous battery working time | 6-8 hours |

Stability | Temperature drift:0.2uV / ℃ (0 ~ 60 ℃) |

Zero drift: ≤ 0.1% / 8 hours / FS | |

Calibration range | full-scale calibration |

Ambient temperature | 0 ~ + 60 ℃ |

Ambient humidity | ≤ 80% |

Allowable overload | 150% |

Power supply method | No. 5 nickel-cyanide battery pack / 220V AC for 4 to 6 hours |

2. The upper fixture of the instrument:

Model | AJJ-013 | AJJ-014 | AJJ-015 |

Scope of application | It is mainly used for tensile testing of buttons and toys | ||

Maximum load | 500N | ||

Send Request

You may also like