Cleaning washer CTLW-120

The fully automatic container cleaning machine, also known as the laboratory bottle washing machine, is suitable for cleaning and drying various types of containers such as injection bottles, test tubes, beakers, pipettes, triangular bottles, volumetric f

The significance of automated cleaning:

1. Standardized cleaning treatment ensures uniform cleaning effect and reduces uncertain factors caused by human operation;

2. Easy to verify and save records, convenient for traceability management;

3. Reduce the risk for staff and avoid injury or infection during manual cleaning process;

4. Cleaning, disinfection, and drying are fully automated, reducing equipment and labor costs and saving costs;

Structural characteristics:

1. Material: Cleaning chamber: SUS316L, shell: SUS304;

2. Imported high-efficiency circulation pumps from Europe, with stable and reliable cleaning pressure;

3. Design and arrange cleaning positions based on fluid mechanics principles to ensure the cleanliness of each item during cleaning;

4. Optimize the rotating spray arm of the flat mouth nozzle design to ensure 360 ° coverage without dead corners during spraying;

5. Dual water temperature control ensures the entire cleaning water temperature;

6. Cleaning solution can be set and automatically added;

7. Built in HEPA high-efficiency filter ensures the cleanliness of dry air; Synchronize the drying water circulation pipeline to avoid moisture contamination of the cleaning system; Dual temperature control to ensure dry temperature;

Operation control:

1. PLC (Programmable Logic Controller) control system, stable and reliable;

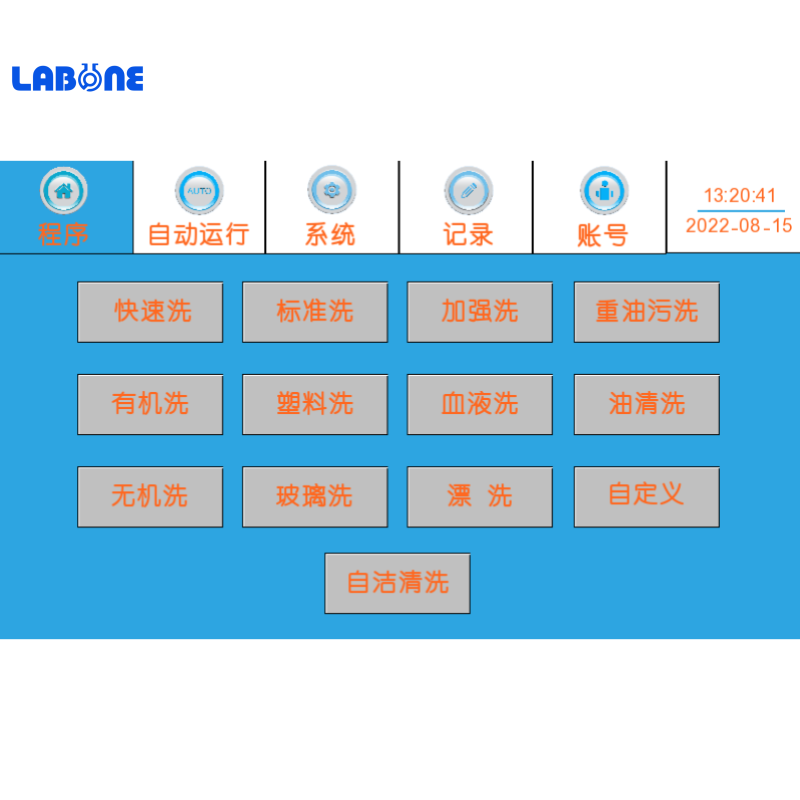

2. The cleaning program can be freely combined and used as needed;

3. 7-inch color LCD touch screen, with all device operation information displayed in text;

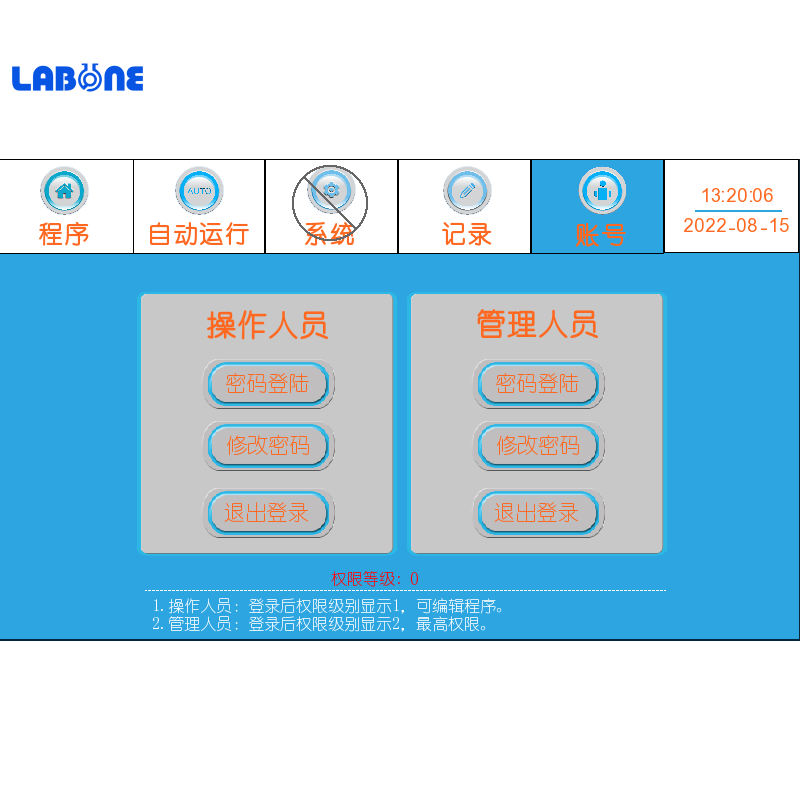

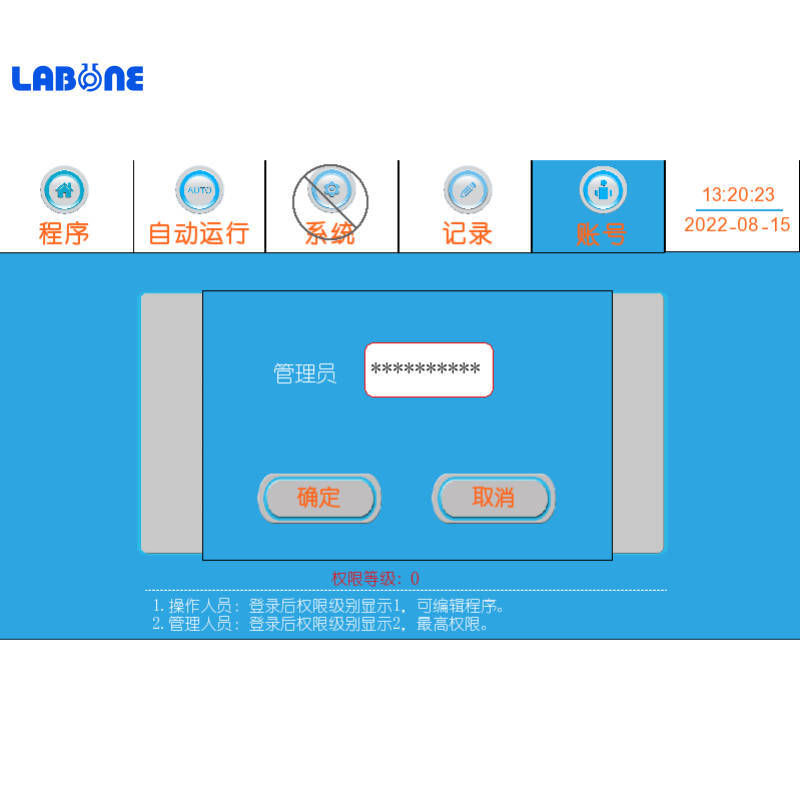

4. Level 3 password management, which can meet the use of different management permissions;

5. Equipment fault self diagnosis and sound/text prompts;

6. Automatic data storage function for cleaning;

7. USB cleaning data export function;

8. Micro printer data printing function (optional);

Security protection function:

1. Two point electronic door lock to prevent arbitrary opening;

2. Dual temperature protection for water temperature and air temperature;

3. High temperature automatic protection for circulating pumps;

4. Power outage protection function;

5. Design water seals for drainage pipelines to prevent back flow of sewage;

Specifications:

Items | Model | Value |

Cleaning | Capacity (L) | 120 |

Washer Load Level | 1 | |

Water Wash Power (KW) | 0.4 | |

Water Heater Power KW) | 5 | |

MAX. Power (KW) | 6 | |

Water Consumption/Cycle (L) | 17 | |

Tank Internal Temperature (℃) | 0~99 | |

Water Supply Pressure (Mpa) | 0.3~1.0 | |

Peristaltic Pump for Cleaning Agent | 2 independent pumps control detergent agent and neutralizing agent | |

Cleaning Agent Level Sensor | YES | |

Washing Pump | Sweden 400L/min | |

Drying | Drying Function | YES |

Steam Condenser | YES | |

Dry Power (KW) | 3 | |

Control System and Traceability | Control System | 7" color LCD touch screen display,microprocessor |

Cleaning Program | 12 pre-set programs (editable)+99 PLC free programming | |

Password Protection | 3 levels password | |

Safety Emergency Button | YES | |

USB port | YES | |

Integrated printer | Optional | |

Online Monitor Performance of Washing | Optional | |

Dimensions & Weight | Chamber Dimension (W*D*H,mm) | 600*629*539 |

Exterior Dimension (W*D*H,mm) | 980*740*870 | |

Package Dimension (W*D*H,mm) | 1110*940*1075 | |

Net Weight (Host only, kg) | 169 | |

Gross Weight (Host with rack, kg) | 200 | |

Others | Door | Double-Layered Glass Door |

Safety Door Lock | YES | |

Built-in RO Water | YES | |

Pump Noise (dBa) | <50 | |

Voltage (V/Hz) | 220V~240V/50~60Hz | |

Certificate | CE+ISO9001 |

Clean the basket rack:

Cleaning rack model | Cleaning rack name | Maximum number of layers that can be placed at a time |

CWIR16 | Single cleaning of 16 1000ml conical flasks and volumetric flasks | one |

CWIR20 | Single cleaning of 20 500ml conical flasks and volumetric flasks | one |

CWIR36 | Single cleaning of 36 250m triangular flasks, test tubes, measuring cylinders, and beakers | one |

CWIR60 | Single cleaning of 60 triangular bottles, test tubes, measuring cylinders, and beakers | one |

CWIR80 | 80 position beaker cleaning rack, capable of cleaning small beakers, centrifuge tubes, volumetric flasks, etc. | one |

CWIR120 | 120 spray columns, capable of cleaning 120 centrifuge tubes, test tubes, and volumetric flasks up to 50ml | one |

CWIR222 | 222 spray columns, capable of cleaning 222 injection bottles and test tubes (+1 set of mesh baskets for cleaning injection bottle caps) | one |

CWIR260 | 260 spray columns, capable of cleaning 260 injection bottles and test tubes | one |

CWIR11218 | 112 spray columns+18 spray columns | one |

CWBRO1 | No spray column, directly placed on the cleaning rack | one |

CWBRO4 | No spray column, equipped with 4 cleaning baskets, can clean a large number of containers such as penicillin bottles and test tubes | one |

CWPR60 | 60 pipettes can be cleaned at a time | one |

CWPR6060 | 60 displacement liquid tube+60 position injection bottle spray column | one |

CWIR10072 | 100 displacement liquid tube+72 position injection bottle spray column, upright cleaning | one |

CWPDR9070U | 70 culture dishes with a diameter of 90mm can be cleaned in one go | one |

CWPDR9070L | 70 culture dishes with a diameter of 90mm can be cleaned in one go | one |

CWIR38 | 38 position measuring cylinder cleaning rack | one |

CWRTR20 | Single cleaning of 20 3-5 meter rubber hoses | one |

Send Request

You may also like