S212-100L 100L Double Layer Jacket Glass Reactor

High quality borosilicate glass 3.3 has good chemical-physical attribute.Low speed booster motor; High torque; no spark;

High quality borosilicate glass 3.3 has good chemical-physical attribute.

Low speed booster motor; High torque; no spark; frequency control, smooth operation.

PTFE rotary seal assembly; Patented product; High vacuum degree and long useful life.

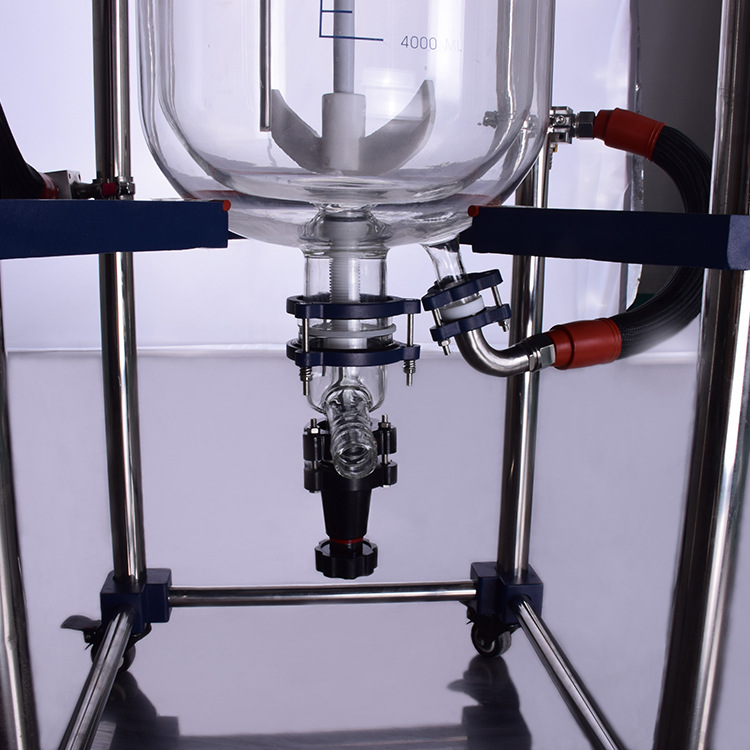

PTFE discharge valve, discharge completely and quickly, no leak/pollution to the solvent.

Selection of our company’s heating and cooling circulating device, we match standard connector and the suitable connection pipe.

Product Description

Glass reactor systems are the essential equipment for mixing, reaction, distillation and filtration in chemistry and pharmaceutical industries. We offer a wide range of glass reactors with volumes from 500mL to 200L. All the glass reactor systems can be modified in our own factory quickly in case any customization is needed from us (dimension,motor power, explosion proof, additional glassware, custom port size, etc).

Different heating or cooling liquids, such as water or oil, can be injected in the interlayer of the jacketed glass distillation reactor for providing a constant temperature for reactions. It also can provide excellent mixing in the reactor under atmospheric or sub-atmospheric pressure. The transparent glass structure can be helpful to monitor the complete reaction.

Glass reactors are designed for synthetic reaction of different types of materials in a controlled temperature and vacuum environment, jacketed filter reactors can be used for single or multi-step reactions and filtrations in the same vessel, production and process scale peptide synthesis. Filter base eliminates material transfers and significantly reduces material losses.

Product Display

Features

1.Dual jacketed model allows you to draw vacuum from the outer jacket, thus protects the circulation fluid temperature and provides a better control.

2.Solvent-resistant PTFE on all sealing components ensures long time durability and operation.

3.All glassware is hand-made from borosilicate 3.3 glass that is heat/cold/corrosion-resistant.

4.Adjustable stirring rate provides great torque or high speed.

5.Patented PTFE stirring rod bearing for reliable and quiet operation.

6.Wide range of temperature operations, from -60°C to 200°C.

7.Large condenser cooling surface for exceptional condensation performance.

8.Rugged stainless steel reinforced PTFE stirrer with anchored agitator, suitable for a wide range of viscous materials.

9.Easily visual operation with digital speed and temperature displays.

10.Heavy duty stainless steel supporting framework with lockable casters for mobility and stability.

11.Easy-to-install modular design

12.Zero dead space bottom valve design

Technical Specifications

Model | S212-10L | S212-20L | S212-50L | S212-100L | SL212-200L |

Reaction Volume(L) | 10L | 20L | 50L | 100L | 200L |

Jacket Volume(L) | 5L | 8L | 12L | 18L | 25L |

Reactor Material | High quality borosilicate 3.3 glass | ||||

Support Frame Material | Stainless steel 304 and coated aluminum | ||||

Neck No. On Lid | 6 | ||||

Rated. torque(N.cm) | 177 | 177 | 177 | 285 | 550 |

Motor power(W) | 120 | 120 | 120 | 200 | 370 |

Rotating speed(rpm) | 0 ~ 600 (customizable) | ||||

Power supply | 220V or 110V / 50-60HZ | ||||

Discharge | PTFE (Teflon) bottom discharge valve with no deadspace | ||||

Working Temp range | -60 to 200°C | ||||

Pressure Range | Full vacuum to atmosphere | ||||

Max jacket pressure | 0.5 bar | ||||

Send Request

You may also like